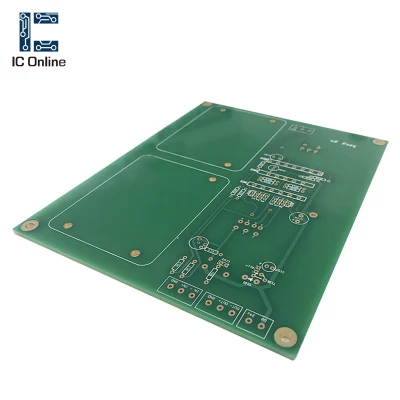

Fr4 Tg 170 Flexible PCB

Package size per unit product 10.00cm * 10.00cm * 10.00cm Gross weight per unit product 0.100kg Product introduction: 2,

Description

Basic Info

| Model NO. | fr4 tg 170 pcb |

| Type | Rigid Circuit Board |

| Dielectric | FR-4 |

| Material | Fiberglass Epoxy |

| Application | Aerospace |

| Processing Technology | Electrolytic Foil |

| Base Material | Aluminum |

| Insulation Materials | Organic Resin |

| Brand | No Brand |

| Transport Package | EXW |

Packaging & Delivery

Package size per unit product 10.00cm * 10.00cm * 10.00cm Gross weight per unit product 0.100kgProduct Description

- Product introduction:

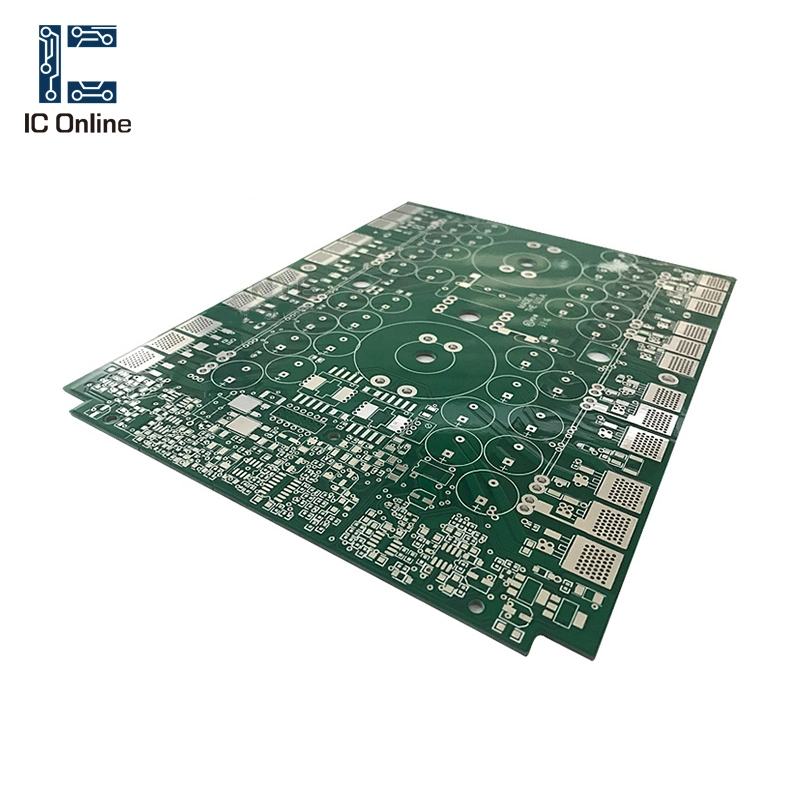

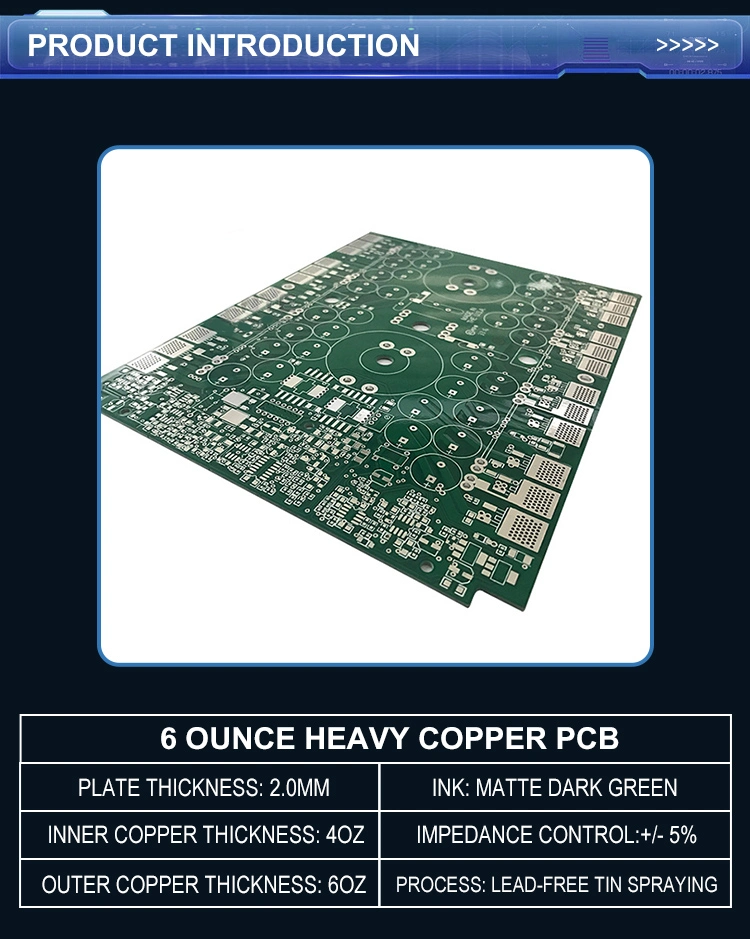

| 6 ounce Heavy copper pcb | |

| Plate thickness: 2.0MM | Ink: matte dark green |

| Inner copper thickness: 4OZ | Impedance control:+/- 5% |

| Outer copper thickness: 6OZ | Process: lead-free tin spraying |

2, Product reason:

In the circuit board industry, the circuit boards with a thickness of 105 um or more are usually called thick copper boards. At present, the thick copper foils mainly used for printed circuit boards are 3 ounces, 4 ounces, 5 ounces, 6 ounces, and sometimes even 16 ounces. The above are 6 ounces Heavy copper pcbs.

Then why use thick copper? Here, we will explain that PCBA is bound to generate heat during its long-term use, which comes from the heating of electronic components, PCB itself and the external environment. Among the three heat sources, the heat of electronic components is the largest, followed by the heat of the circuit board itself. The heating of components is determined by their power consumption. The circuit board carrying high-power components is accompanied by large current. Therefore, when designing a large current circuit board, the conductive layer must be made through large current and circuit board, and then the circuit board's ability to safely withstand the heat generated by large current must be considered.

3, Areas involved:

According to the size of the current that the copper conductor bears, it is proportional to the size of the cross-sectional area of the line. Therefore, the design of increasing the thickness of copper foil or increasing the line width can be used to meet the requirements of high current load. For some power boards with large current and power, more circuits need to be designed in limited space, so the demand for thick copper plates is increasing. At present, thick copper circuit boards are mainly used as high-power or high-voltage substrates. They are mostly used in automotive electronics, communication equipment, aerospace, network energy, planar transformers, power converters, power modules, etc., involving automotive, communications, aerospace, power, new energy, semiconductor lighting, electric locomotives and other fields. This 6 ounce Heavy copper pcb is used in the power converter.

4, Company introduction:

Bente Circuit is a professional printed circuit board manufacturer, which can produce high-quality thick copper circuit board products and can provide up to 16oz copper thick circuit board manufacturing. Similar to these 6 ounce Heavy copper pcbs. Founded in 2011, Bent Circuit is a high-tech electronic manufacturing enterprise specializing in the production of 2-18 layers of high-precision circuit boards, which has passed ISO9001:2015 (certification number: 06922Q17993R1) quality management system certification, SGS certification, and UL certification in the United States and Europe (UL E507367).

| It has obtained ISO9001:2015 (certification No.: 06922Q17993R1) quality management system certification, SGS certification, American and European UL certification (UL No.: E507367) |

5, Factory advantages:

1) Advantages of production capacity: with fully automated advanced equipment configuration and unmanned workshop, high quality and fast completion of large and small batch orders; The business philosophy is "design first, technology leading, quick response and characteristic service". Cooperate with the urgent order and deliver the goods within 8 hours at the earliest.

2) Advantages of quality assurance: ISO:2008 quality management.IQC incoming material 100% inspection;Oxford measuring hole copper,finished copper thickness.Line transfer, resistance welding and leakage.Etch and measure line width,gap.X-ray measurement of nickel deposited gold film thickness.100% on-off test.

3) Advantages of logistics cost: thick copper plates are particularly heavy. Bente Circuit has the advantages of designated fast and slow shipping channels. It has deep strategic cooperation with several large domestic logistics companies, which can completely save logistics costs and transportation time for customers, and truly solve and reduce the customer's own logistics costs.

Our Contact

Send now